Vertere DG1 Turntable / Ortofon 2M Black Cartridge

£2,250.00

Manufacturer : Vertere

Model : DG1 / Ortofon 2M Black

Serial Number : V00702

Packaging : Original

Accessories Included : PSU / Schuko Plug / Interconnect / Manual / Nut / Allen Key / Protractor

Price When New : £3500 ish

1 in stock

Description

Here we have an example of the stunning DG-1 Turntable with Groove Runner Tonearm from Vinyl experts Vertere. It is in very good condition and supplied in original factory packaging along with manual, power supply unit, various plug adaptors, interconnect cable, allen key, protractor, nut and our standard three month warranty. The turntable is fitted with an example of the excellent Ortofon 2M Black Cartridge. However as we have no exact knowledge of the age or amount of use/wear this unit has had, it is not covered by our warranty but as it is a moving magnet design the stylus can always be changed or even upgraded.

Vertere Say….

The DG-1 is the most affordable model in the Vertere record player range, but building it proved one of our greatest design and engineering challenges. It takes a huge amount of work to achieve the ultimate simplicity, delivering the best possible sound from the fewest components. To develop the DG-1, our first ‘plug and play’ record player, we needed to find a way to make it as simple as possible to set up and use, while at the same time delivering class-leading sound – and the potential for future upgrading. That involved examining every element of the design, rethinking the way record players work, and removing every superfluous element that got in the way of our ultimate aim: getting you, the listener, as close as possible to your music. From the plinth to the tonearm and its bearings, everything has been redesigned and re-engineered, developing some of the basic principles of a record-playing system while completely rethinking others. The result is an elegant record player that looks like no other, but draws on the engineering of our flagship models to deliver outstanding performance and ease of operation at a newly affordable price.

The motor is arguably the most important part of any record player: it’s the only source of energy for the signal generated by the cartridge and fed out to the amplifier, so quality and accuracy is vital. The DG-1 motor system is derived from that developed for the flagship RG-1 Reference Motor Drive: it uses the most advanced motor drive, delivering the best possible performance. The motor itself is a low voltage 24-pole Precision Synchronous design, individually tuned for the lowest noise and with an off-board power supply. It’s controlled by a microprocessor PCB, addressable during manufacture to ensure accuracy and programmable for future upgrades, with copper/stainless steel shielding to avoid both inward and outward interference.

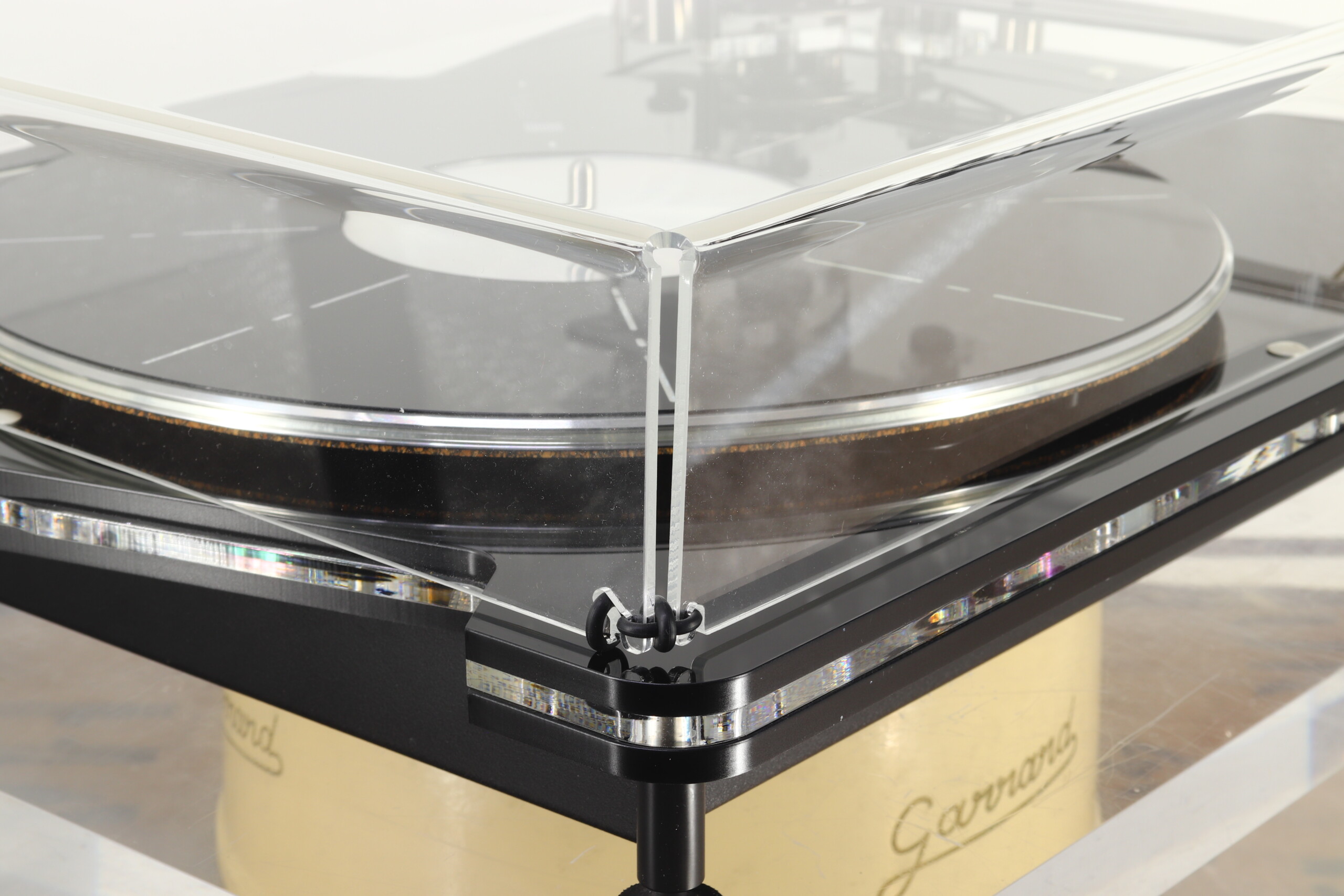

Drive to the platter is via a precision machined aluminium alloy pulley on the motor and a bespoke silicone rubber drive belt, with electronic speed change for ease of use. The platter itself is also precision machined alloy, to which is bonded a PETG record interface mat and, on the underside, cork/Neoprene/nitrile bonded disc to control platter resonance.

The platter sits on a highly polished stainless steel spindle, which rides in a main bearing housing using a super precision tungsten carbide ball, avoiding the need for complex regimes of lubrication. That’s another example of the simplification of this record player to optimise performance.

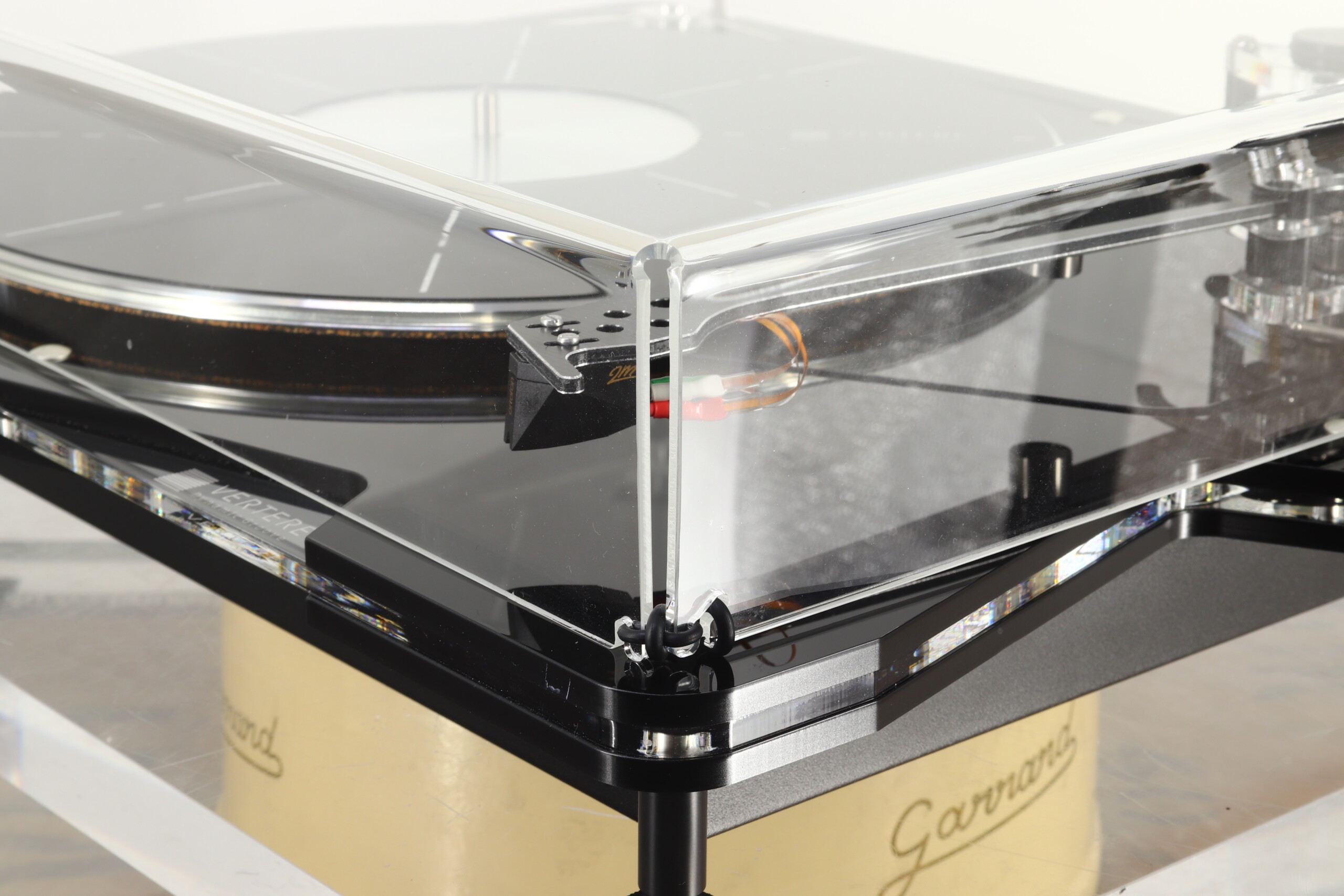

The DG-1 arm is uniquely Vertere, and differs from established thinking in its use of a flat profile in place of the usual tube – conventional arms use tubes for stiffness, but these bring all kinds of problems with resonances, and thus the need for damping. The DG-1’s three-layer, non-resonant tonearm beam avoids these problems and, in place of conventional tonearm cabling, uses a flexible PCB sandwiched into the arm itself to carry signal from the cartridge to the output terminals. It’s a very neat and – if we say so ourselves – clever solution.

The same goes for the bearings allowing the arm its horizontal and vertical movement: there aren’t any – well, not in the conventional sense! Many solutions have been sought over the years for these precise bearings, but for the DG-1 we have developed a very simple solution: twisted nylon threads – one for movement in the horizontal plane, and two for the vertical axis.

These threads have many advantages, not the least of which is simplicity: they exhibit none of the stiction – or initial resistance to movement – of conventional bearings, are super-light and noiseless, and the twist of the thread controls and damps the movement of the arm.

Completing the arm are a stainless steel counterweight and tracking adjustment weight, giving a total solution that’s as simple and elegant as it is innovative.

Like the tonearm, the DG-1 plinth is of a sandwich construction, using non-resonant cast acrylic to form the main plinth and the sub-plinth. This incorporates the speed selector switch, the speed indicator and user-selectable standby mood-lighting, and the silicone rubber isolation between the two sections – the plinth and the platter assembly. All are sandwiched between the layers of acrylic for a clean, sophisticated look to complement any home, while the whole assembly sits on a steel chassis, chosen for optimal stability, which houses the motor drive circuit and the motor, and is supported by three adjustable feet.

Oh, and remember what we said about simplicity? The DG-1 comes complete with a non-resonant acrylic dust-cover, its hinges integrated into the plinth for a clean look and durability

Specifications:

Turntable:

Type: Belt Drive

Motor: 24 Pole Synchronous; Acetal Spindle Thrust Bearing

Motor Mount: Axially De-coupled

Pulley: Aluminium Alloy

Drive Belt: Bespoke Silicone Rubber

Platter: Precision Machined Aluminium Alloy; PETG Bonded Record Interface Mat; Underside Bonded Resonance Control Disc

Bearing Spindle: Stainless Steel; Super Precision Machined & Polished

Roundness / Concentricity: < 5 Microns

Bearing Housing: Brass; Super Precision Machined; Bore Tolerance < 5 Microns; Super Precision Tungsten Carbide Ball

Plinth Structure: 3 Layer Acrylic; Top and Sub-Plinth, Internally Illuminated

Isolation System: 4 Point, Bespoke Silicone Rubber; Support Structure; Steel Chassis; Three Adjustable Feet

Motor Drive: Advanced Microprocessor Controlled; Fully Programmable & Motor Noise Reduction

Speeds: 33.3 & 45 rpm (+/- 0.2%); Electronically Selectable

Dust cover: Non-resonant Acrylic

Power Supply: Wall Adaptor Type; UK, US, EU & AUS Exchangeable Plugs; 100 – 240 Vac with 1.5m Cord

Dimensions: 469 (W) x 384 (D) x 130 (H) mm (Including Dust Cover)

Weight 8.0 kg

Tonearm:

Type: Fixed Axis Bearing

Tonearm Beam: Aluminium/Polymer Sandwich

Bearing Structure: Twisted Nylon 6.6/6 Thread

Counterweight: Stainless Steel with Adjustable Tracking Weight Block

Internal Wiring: Gold Plated Flexible PCB; With Gold Plated Cartridge Tags; One Piece From Cartridge To Output; RCA Sockets

Effective Length: 240 mm

Overhang: 17.5 mm

Offset Angle: 22.9°

Weight: 280 g

Ortofon Say….

The 2M Black is the new moving magnet flagship from Ortofon. The 2M black is graced with a Shibata diamond stylus – the same diamond as on the acclaimed MC Jubilee. Its slim, highly polished profile allows an exceedingly wide contact area to the groove walls and ensures notably detailed reproduction throughout the spectrum, including even the most high-frequency groove information. Users of the 2M Black will enjoy the benefit of impeccable sound quality, along with reduced record & stylus wear, and reduced distortion and phase error as a result of the diamond’s improved tracking geometry. The cartridge body used for the 2M Bronze and 2M Black is manufactured from a newly-developed Noryl plastic/glass combination, a revolutionary material which ensures high rigidity while eliminating unwanted resonances. The 2M Bronze and 2M Black use a special upgraded engine, featuring split pole pins with a silver-plated copper wire.

2M cartridges are designed for precise and accurate retrieval of the information in the record groove. Ortofon’s philosophy is to play the record sound as accurately as possible, without colouring the sound in any way. Both the 2M Bronze and 2M Black have diamonds which are cut and polished to the highest standards of the industry. The 2M design has also been optimized for easy mounting on to a tonearm; the weight and size of all 2M models is well-suited to fit the most common turntables on today’s market. The 2M Bronze and 2M Black also have interchangeable stylus units, and replacement styli are readily available in the UK.

The spectacular 2m Black has become the flagship of 2M, and all Ortofon moving magnet cartridges. 2M was also the last product designed by Ortofon’s former chief engineer, Per Windfield. He developed the 2M series over the final 2 years of his 30 year tenure with Ortofon.

Specifications:

Output Voltage (at 1 kHz, 5 cm/sec): 5 mV

Channel Balance at 1 kHz: 1 dB

Channel Separation at 1 kHz: 26 dB

Channel Separation at 15 kHz: 1-5 dB

Frequency Range (at -3 dB): 20 Hz – 31 kHz

Frequency Response 20 Hz – 20 kHz: +2 / -0 dB

Tracking Ability at 315 Hz: Typically 80 μm

Compliance, Dynamic, Lateral: 22 μm / mN

Stylus Type: Nude Shibata

Stylus Tip Radius r / R: 6 / 50 μm

Tracking Force Range: 1.4 – 1.7 g (14 – 17 mN)

Recommended Tracking Force: 1.5 g (15 mN)

Tracking Angle: 20º

Internal Impedance / DC Resistance: 1.2 kΩ

Internal Inductance: 630 mH

Recommended Load Resistance: 47 kΩ

Recommended Load Capacitance: 150 – 300 pF

Cartridge Colour Body / Stylus: Black / Black

Cartridge Weight: 7.2 g

Reviews

To read a review from Hi-Fi+ magazine please click here

For a second opinion from Hi-Fi News magazine please click here