Your basket is currently empty!

Rega P7 Turntable – Silver / Goldring 1042 Cartridge

£735.00

Manufacturer : Rega

Model : P7 / Goldring 1042

Serial Number : 358518

Packaging : N/A

Accessories Included : Original Mat / Manual

Price When New :

Out of stock

Description

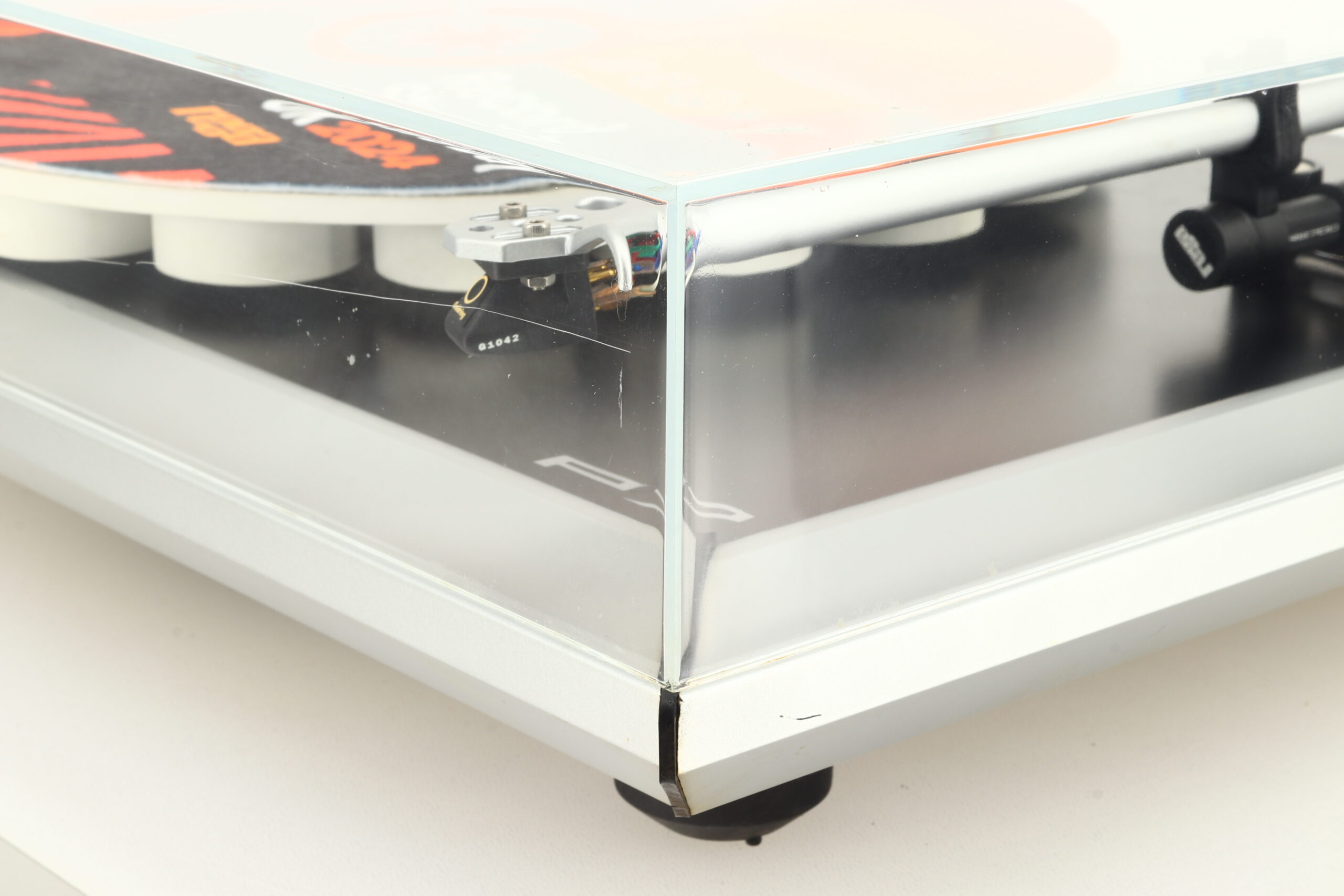

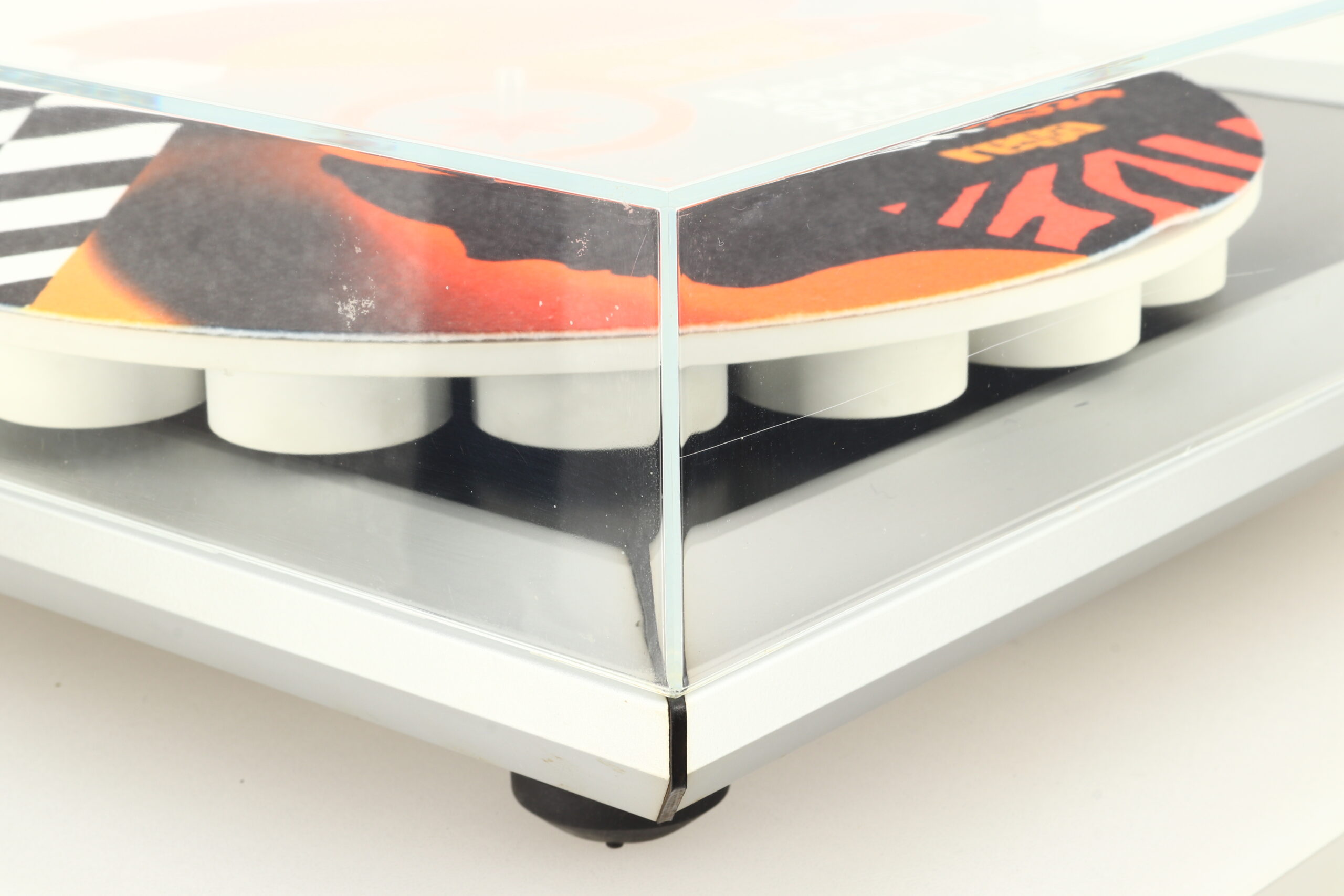

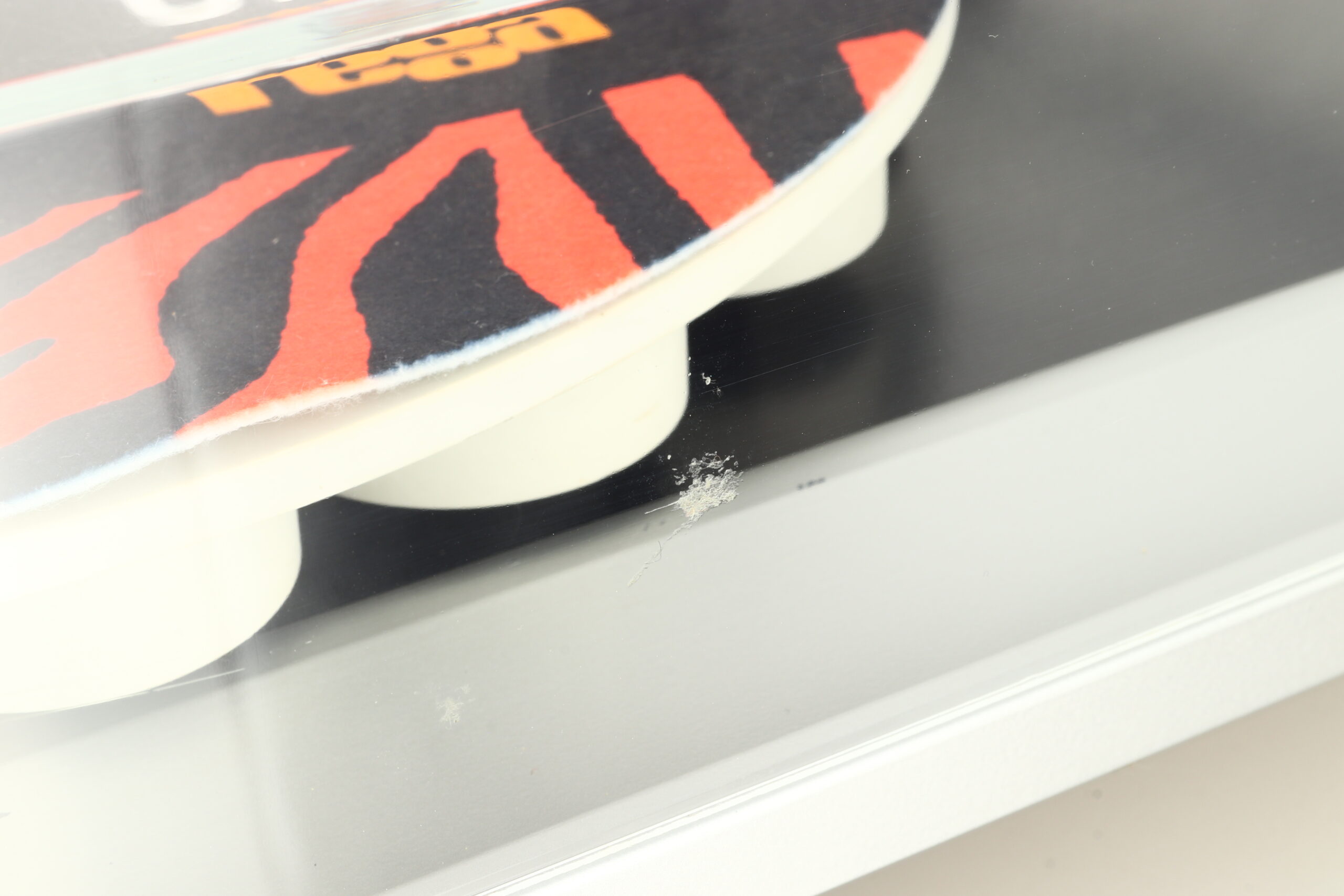

Here we have a P7 turntable from British vinyl experts Rega Research. It comes in good condition with a couple of minor blemishes on the plinth and some light marking to the lid – please see photographs. It will be professionally packaged and supplied with standard a TTPSU (Turntable Power Supply Unit), mains (wall wart) PSU, manual, original platter mat (rather creased) and a 2024 Record Store Day (replacement) mat. This package also comes with our regular three month warranty but please note it does not cover the fitted Goldring 1042 cartridge.

Rega Say….

Rega’s philosophy is to make high quality products at sensible prices, as a means of reproducing music as faithfully as

possible. Rega is committed to the design and development of new and existing products, both in hi-fi and other

areas, that will perpetuate Rega’s values of quality and value for money.

The Rega P7 has been designed to be effective, easy to use and above all – to reproduce music better than any other turntable. We have omitted all the usual gimmicks and genuinely concentrated the manufacturing costs on the high quality components and design necessary to reproduce records accurately.

For example: a complex sub-chassis suspension is normally necessary to reduce motor noise. However they are difficult to maintain and degrade performance. Rega have designed a unique phase adjustable power supply which eliminates motor vibration at source and therefore eradicates the need for a suspension.

Rega’s design skill and the use of extremely high quality components ensure that your turntable will perform at its optimum.

The P7 has a new tonearm, the RB700, improving greatly on the previous model, the RB600. The aluminium tube has been specially coated in a unique finish and the entire bearing housing has been redesigned and is now manufactured to even higher tolerances.

The tonearm tube itself (which is a one piece silicone/aluminium casting) is very rigid, whilst being low mass. The tonearm assembly is concentrated around precision, hardened stainless steel, miniature ball races of the highest quality. The bearings fit on to ground shafts and into the tonearm using interference fits. This means that no adhesive is required and therefore none of the associated (component – adhesive – component) losses in rigidity prevail. It is fitted to the plinth by a 3-point fixing which is CNC machined out of a single solid block of Stainless steel. This provides the strongest most rigid base structure possible for the tonearm and causes less stress on the plinth and the RB700’s bearing housing, and therefore the least possible resonance.

The RB700 tonearm is designed to make cartridges work harder, maximising the cantilever acceleration and travel as much as possible with the utmost accuracy within the cartridge body thus providing new levels of information.

The platter is produced from a ceramic oxide powder which is compressed, fired and diamond ground to size. (Because this platter is as stiff and hard as sapphire, the only improvement that can be made would me to make it from diamond.) This is a first in the industry at volume production levels.

Even so, each platter takes many hours to produce. Expensive detail design ensures it only sits on three points on the centre hub. We have also used new techniques to achieve better speed stability of the turntable by using ceramic weights to provide a flywheel effect to the platter.

The new P7 plinth is made from an even lighter material than the original Planar which again offers advantages over its predecessor. The plinth is of a skeletal design. This allows the mass to be reduced and the rigidity increased in comparison to a solid section construction. All organic materials used in the production of the plinth and surround are obtained from sustainable sources.

The motor is a high specification, P9 24V twin phase synchronous unit controlled by Rega’s unique and innovative TT PSU power supply. The motor drives the computer-numerically-controlled (CNC) machined pulley and sub platter/hub-bearing assembly via a twin belt drive. Two belts are used so that any small inaccuracies in one belt will be cancelled out by the second, giving unusually low levels of wow and flutter.

The compact TT PSU uses exactly the same high stability crystal locked low distortion sine wave generator as is used in the heart of the P9 power supply.

This, along with an efficient drive amplifier fed from a stabilised DC power supply, generates a 24V AC balanced signal of less than 0.05% distortion, which is completely un-affected by any changes in the mains/line voltage and conditions. This then drives the improved Rega anti-vibration circuit, which is situated beneath the turntable.

The speed change is achieved by changing the frequency of the drive voltage; this is because the speed of the platter and motor is directly proportional to the motor drive frequency. A relay switches in the required phase compensation & anti vibration circuit to eradicate motor vibration to a minimum at both speeds.

We have used the highest quality purpose designed high current power and phono connectors and low noise, wide bandwidth interconnect cable. These are genuine professional products and are the best available for the job. Do not attempt to fit any other wires or cables.

Specifications:

Drive method: belt drive

Motor: 24V AC synchronous

Platter: Ceramic

Speeds: 33.3 and 45 rpm

Reviews

To read a review from Hi-Fi Choice magazine please click here